Pp-r90 daraja egg'a mog'or

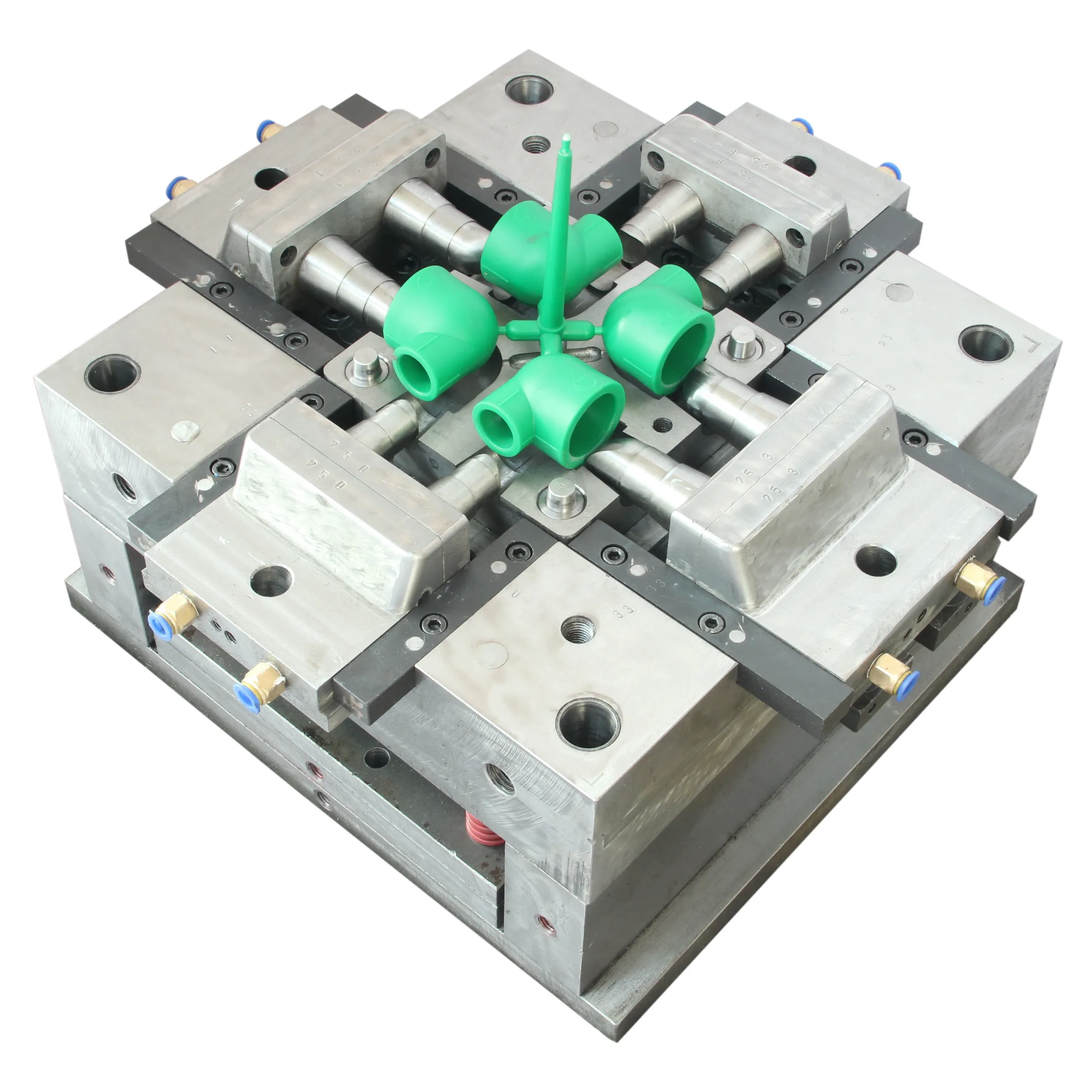

PP-R 90-Degree Elbow Mold: Design and Functionality A PP-R 90-degree elbow mold is a precision tool used in the injection molding process to manufacture polypropylene random copolymer (PP-R) pipe fittings, specifically 90-degree elbows. These fittings are essential in plumbing and HVAC systems, enabling smooth directional changes in piping networks while maintaining flow efficiency and pressure resistance. The mold’s design and construction play a critical role in ensuring the quality, durability, and dimensional accuracy of the final product. Key Features of the PP-R 90-Degree Elbow Mold 1. Material and Durability The mold is typically made from high-grade tool steel, such as P20, H13, or stainless steel, to withstand high injection pressures and prolonged use. Hardened steel components enhance wear resistance, ensuring a long service life even under continuous production cycles. 2. Precision Engineering The mold cavity and core are CNC-machined to exact specifications, guaranteeing tight tolerances (typically within ±0.02mm) for consistent fitting dimensions. The 90-degree bend angle must be precisely maintained to ensure proper alignment when installed in piping systems. 3. Cooling System Design Efficient cooling channels are integrated into the mold to regulate temperature during the injection process. Uniform cooling minimizes warping and internal stresses in the PP-R elbow, improving product consistency and reducing cycle times. 4. Ejection Mechanism The mold incorporates ejector pins or sleeves to smoothly release the molded elbow without deformation. Proper ejection design prevents surface defects and ensures smooth demolding, even for thicker-walled fittings. 5. Surface Finish The cavity and core surfaces are polished or textured to achieve the desired finish on the PP-R elbow. A smooth interior surface reduces friction in fluid flow, while a matte exterior may be preferred for handling and aesthetics. Production Process The PP-R material is heated to a molten state and injected into the mold under high pressure. After filling the cavity, the material cools and solidifies into the elbow shape. The mold then opens, and the finished fitting is ejected. Post-processing, such as deburring or quality inspection, may follow. Applications PP-R 90-degree elbows are widely used in hot and cold water systems, industrial pipelines, and chemical transport due to their corrosion resistance, thermal stability, and leak-proof joints. The mold must produce fittings that meet international standards (e.g., ISO 15874, DIN 8077). Conclusion A well-designed PP-R 90-degree elbow mold ensures high productivity, dimensional accuracy, and long-term reliability of the fittings. Its robust construction, precision engineering, and efficient cooling system contribute to cost-effective manufacturing while maintaining the high performance expected in modern piping systems.

mahsulot

Tasniflash:

-

Pp ochko'zlik panchasi

kategoriya: Pp trubkasi mog'orKoʻrishlar: 605ishlab chiqarish raqami:chiqarish vaqti: 2025-09-16 23:46:09Pp ochko'zlik panchasiElement nomi: pp yarashmali tirsagi 90º trubkaBo'shliqlar: 16 taCavityMaterial: ppmog'or tuzilishi: yog 'silindrining tuzilishiBo'shliq / yadro po'latkasi: 2738 OrtiqchaYadro / bo'shliqning qattiqligi: HRK vakuumini issiqlikni davolashdan keyin 40-45 darajaIn'ektsiya shakllantirish mashinasi: 380t Taizhou Xuang Yanhongjin plastik ld1, plastik mog'or ishlab chiqarishda ixtisoslashgan mahsulotlar quyidagilardan iborat: PPR PE PP PE va boshqa quvur mog'orlari, tovar aylanmasi, plastik valve mog'or, plastik valve mog'or, shisha mog'or, shisha mog'or, shisha mog'or, shisha m... -

40mm PPR TIBLASH 90 daraja trubkasi

kategoriya: PPR trubkasi mog'orKoʻrishlar: 538ishlab chiqarish raqami:chiqarish vaqti: 2025-10-23 18:12:1040mm PPR TIBLASH 90 daraja trubkasiMog'or nomi:40mm PPR TIBLASH 90 daraja trubkasiBo'shliq: 2 bo'shliqlarMold Hajmi: 20-50 mmMog'or po'latkasi: 2738 yoki 718 yil bo'shliq va yadrosi uchunDarvoza: O'chirish to'g'ridan-to'g'ri darvozasiMold tuzilishi: Diagonal qo'llanma ustuni slayder tuzilishiYadro / bo'shliqning qattiqligi: HRK 32-45 darajadan keyin issiqlikni davolashdan keyinIn'ektsiya shakllantirish mashinasi: 250TTaizhou Xuangyan Xong Jin Mold Co., MChJ 2002 yilda tashkil etilgan. Biz 23 yildan ortiq vaqt davomida magistralni ishlab chiqarish va ishlab chiqarish bo'yicha professionalmiz.Bi...

Yangiliklar

Tasniflash:

-

[Company News]Customer Photo

2025-12-09 21:33:14

ish

Tasniflash:

video

Tasniflash:

Hozircha qidiruv natijalari yo'q!

yuklab oling

Tasniflash:

Hozircha qidiruv natijalari yo'q!

ishga qabul qilish

Tasniflash:

Hozircha qidiruv natijalari yo'q!

Tavsiya etilgan mahsulotlar

Hozircha qidiruv natijalari yo'q!

Whatsapp

Whatsapp Telefon

Telefon